Wax coating, PE coating, silicone coating and PLA coatings are applied to custom food papers. These types of coatings offer benefits like moisture resistance and non-stick properties. Plus, it protects against grease and oxygen.

But have you ever wondered how coatings play a safe role in food grade papers? These coatings act as protective layers to ensure food remains safe. Without them food paper would simply absorb oils, fall apart or fail to protect the meal inside.

So, let’s learn a little more about the coatings on food paper that can be beneficial for food chains, businesses, restaurants, cafes, and even households.

Different Types of Coatings Used on the Food Paper for Various Purposes

The main types of coatings for food-grade packaging papers are:

1. Polyethylene (PE) Coating on Custom Fry Paper

Polyethylene (PE) coating is one of the most widely used options for food packaging papers, such as hot wrap paper, fry paper, and more. It creates a smooth, water-resistant layer that protects against moisture and grease. So if you are a food truck, restaurant or café owner, make sure to choose hot paper or any other food paper type with a PE coating for maximum benefit.

2. Silicone Coating on Parchment Papers

Silicone-coated food papers are often used for baking and cooking. The silicone layer prevents sticking that making it perfect for parchment paper and food basket liners. It also provides heat resistance which allows the paper to handle high oven temperatures.

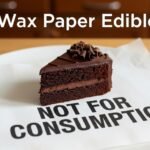

3. Wax Coating on Wax Papers

Wax-coated paper has been used for decades in the food industry. It provides a simple barrier against moisture and grease. Wax-coated paper is popular for wrapping sandwiches, deli items, and baked goods. However this paper does not handle high heat well and is not suitable for baking. Make sure to do it only with precautions.

4. PLA (Polylactic Acid) Coating on Burger Wrapping Paper

PLA is a bioplastic coating made from renewable resources such as corn starch or sugarcane. It provides a moisture barrier similar to PE but is compostable under industrial conditions. You can use it on the greaseproof paper, hot paper and more. As a food brand you can opt for it for your customized food papers to impress customers more easily.

Fluorocarbon-Free Water and Oil Barrier Coatings for All Food Papers

In recent years there has been a concentrated shift toward offering water-based or bio-based coatings that provide the same protection without harmful substances. This also ensures that the papers used for food wrapping can withstand any food product contact and do not harm human health.

What Coatings are Food Safe? Select with Certifications

Not all coatings are suitable for food contact which is why safety standards are important. must Food-safe coatings be FDA-approved or certified by relevant authorities. Silicone, PE, wax, and PLA are among the safest options for food storage and presentation. It’s simple to choose coatings for custom food paper that align with the type of products you plan to store on it. Just make sure to verify that the inks, adhesives, and coatings used are all food-grade and tested for safety.

Food Business Owners Can Grab Any Coatings for the Wrapping of Their Food Items

About 65% of American businesses are using custom printed food paper for their protection as well as for making their presentation top-notch. Plus, many of the suppliers of food paper offer the option to get the coatings on one side or on both sides of the paper. You can choose one that matches your needs perfectly.

Concluding Words

Coatings on food wrapping papers are more than just surface finishes. These are the most important elements that make food packaging safe and suitable for food contact. By selecting the right one, you can ensure the food is served in style while also ensuring no harm is done to health with harmful chemicals.

USA

USA

UK

UK

CA

CA