Not Sure Where to Start? We’ve Got You

| Material | Greaseproof treated paper |

| Weight | 40-45 lb basis weight |

| Thickness | 2.5-3.0 mil |

| Finish | Smooth with grease-resistant coating |

| Certifications | FDA approved for direct food contact |

| Packaging | Boxed in protective cartons |

| Box Dimensions | Varies by size ordered |

| Storage | Store in cool, dry place away from direct sunlight |

| Shelf Life | 2 years when properly stored |

At WaxPapersHub, we make it easy to create custom wrapping paper that’s truly your own. We help you print your logo simply on the paper to attract more customers.

We can repeat your logo across the sheet in one or two colors for a simple and stylish look. You just have to communicate your needs.

Let’s get creative you can use your logo, brand icons, or even custom text in a repeating pattern that makes your wraps instantly recognizable.

Opt for full-color designs and colors that cover the entire sheet. These are perfect for bold branding and maximum impact.

Add your logo with text, taglines, social media handles, or other brand messaging with just a few clicks. .

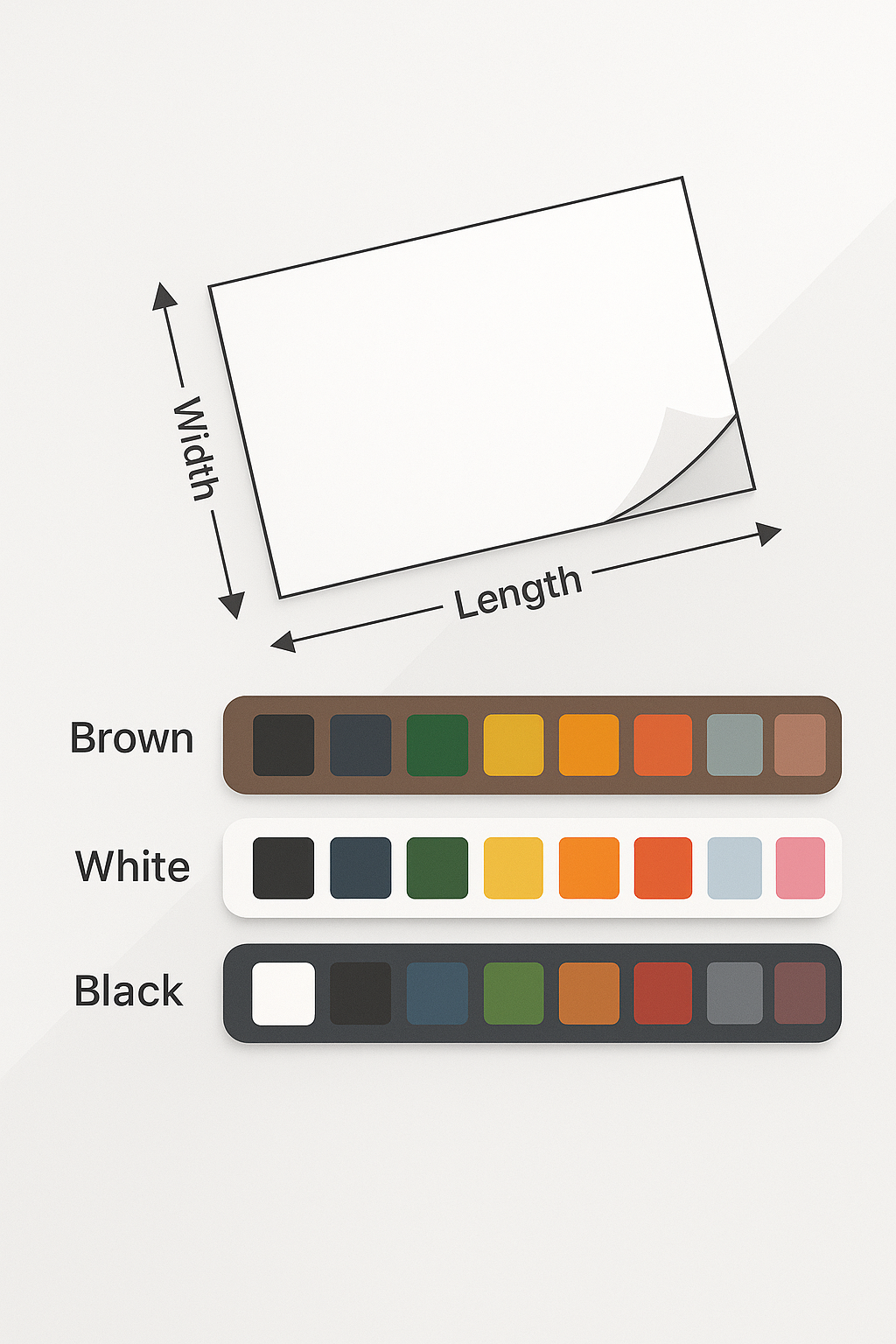

Choose your base color from our available options:

White, Natural Kraft, Green, Blue, Pink

We offer up to 4-color (CMYK) printing for vibrant & detailed designs. PMS matching is available too; just let us know

We have an expert team that can help create custom designs for your food papers.

Vector Formats (Preferred):

Raster Formats (300 DPI minimum):

| 1 | 4″ x 4″ | 5″ x 5″ | 6″ x 5″ | 6″ x 6″ |

| 2 | 7″ x 5″ | 7″ x 7″ | 8″ x 5″ | 8″ x 6″ |

| 3 | 8″ x 8″ | 8.5″ x 11″ | 9″ x 5″ | 9″ x 6″ |

| 4 | 9″ x 9″ | 10″ x 5″ | 10″ x 6″ | 10″ x 8″ |

| 5 | 10″ x 10″ | 10.75″ x 10″ | 12″ x 6″ | 12″ x 8″ |

| 6 | 12″ x 9″ | 12″ x 10″ | 12″ x 12″ | 13″ x 6″ |

| 7 | 13″ x 9″ | 13″ x 10″ | 13″ x 13″ | 14″ x 12″ |

| 8 | 15″ x 9″ | 15″ x 10.75″ | 15″ x 12″ | 15″ x 13″ |

| 9 | 16″ x 12″ | 17″ x 11″ | 18″ x 10″ | 18″ x 12″ |

| 10 | 18″ x 13″ | 20″ x 10″ | 20″ x 12″ | 20″ x 13″ |

| 11 | 20″ x 15″ | 20″ x 18″ | 20″ x 20″ | 20″ x 25″ |

| 12 | 20″ x 28″ |

No reviews yet. Be the first to review this product!